What is Worm Gearbox?

In Automation equipment market Worm gearbox and planetary gearbox are very famous. in this article we are going to introduce the differences in these two models. A worm gearbox is a type of gearbox that consists of a helical screw and a gear wheel known as a worm gear. These gearboxes are used to increase torque and reduce speed in mechanical systems. The unique feature of this type of gearbox is the helical screw, which is shaped like a rod and is wound around during rotation. When the worm screw rotates, it creates linear motion along the axis of the screw.

Due to features such as sudden speed reduction, precise speed control, and the ability to transfer torque over a wide range, this type of gearbox is used in various industries, including robotics, automotive manufacturing, and advanced power generation.

Advantages of Worm Gearbox

- Increase in Torque: A worm gearbox is very good for increasing torque. The geometric shape of the worm screw facilitates the conversion of rotational motion into linear motion, resulting in an increase in torque. This feature makes the gearbox effective in applications that require higher torque with lower rotational speed.

- Due to the reduced interaction of mechanical components, worm gearbox has longer lifespan.

- Diverse Applications: Due to its inherent features in transmitting torque and speed across a wide range, worm gearboxes are effective in a variety of applications. These include industrial machinery, transportation systems, and construction equipment.

Disadvantages of Worm Gearbox

- Reduction in Output Speed: Worm gearboxes are primarily use for increasing torque, but this results in a decrease in output speed. In some applications that require high rotational speed, this limitation may be considered a drawback.

- Heat Generation: In the motion transmission process, a worm gearbox may generate high temperatures, leading to heat losses and a reduction in efficiency. This issue typically requires the implementation of a cooling system or other heat management solutions.

- Worm gearboxes may have a larger size and weight compares to some other types of gearboxes. This issue becomes significant in cases where limited space or weight of components is crucial.

- Worm gearboxes tend to have lower efficiency in comparison to some other types of gearboxes. This is primarily due to the sliding action between the worm and worm wheel, which generates more friction and heat, leading to energy losses.

The Operation of Worm Gearbox

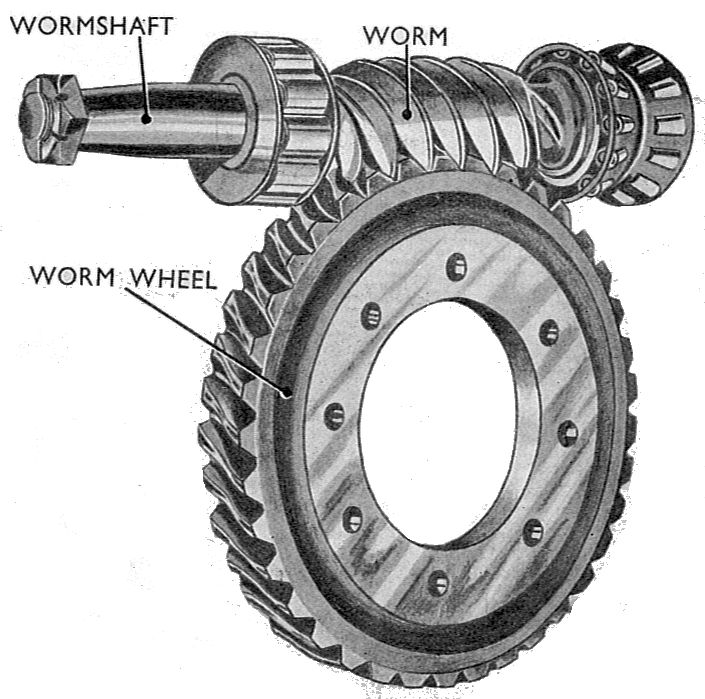

A worm gearbox is a mechanical power transmission system consisting of two main elements, namely the worm screw and the worm gear.

The worm screw resembles a rod with a linear thread. When the worm screw rotates, it creates linear motion in the form of a rod. This linear motion is of special importance in transmitting motion to the worm gearbox system, and the worm gear is designed in the shape of a specific gear. The linear motion of the worm screw affects this worm gear. The worm gear transforms linear motion into rotational motion.

It operates using a worm screw and a worm gear. When the worm screw rotates, it creates linear motion along the longitudinal axis of the screw. The following describes how a worm gearbox works.

- Rotation of the Worm Screw:

Initially, the worm screw, resembling a rod of a specific size, rotates. This rotational motion of the helical rod leads to linear descent.

2. Linear Motion of the Worm Screw:

Due to the unique shape of the worm screw, its points move towards the end of the longitudinal axis as it rotates. This linear motion is of special importance in transmitting motion to the intermediate system of the worm gearbox.

3. Effect on the Worm Gear:

The linear motion of the worm screw affects the worm gear. This kind of gear is designed in a specific way to synchronize with the linear motion of the worm screw and convert linear motion into rotational motion.

4. Transmission of Rotation to the Output:

The rotational motion obtain from the worm gear is transfer to the output system. This can be connected to a rotating shaft or a system that requires rotational motion with high torque and low speed.

In summary, in this model of gearbox, using a worm screw and worm gear, converts rotational motion into rotational motion with high torque and low speed. This characteristic makes it ideal for applications requiring increasing torque and reducing rotational speed.

Planetary Gearbox VS. Worm Gearbox

The main difference of a worm gearbox from other types lies in the geometric shape of the worm screw. In a worm gearbox, the worm screw is in the form of a conical rod during rotation. This geometric shape creates linear motion along the axis of the screw.

By changing the direction of rotation of the worm screw, the linear motion generated by the screw causes the rotational motion of the worm gear connected to it. This arrangement results in an increase in torque and a decrease in speed. Due to this characteristic, worm gearboxes are typically used in applications that require the transmission of torque at lower rotational speeds, such as in industrial machinery and heavy equipment.

In general, the main difference in a worm gearbox lies in the geometric shape of the worm screw and how it influences both linear and rotational motion in the gearbox system. Big Diamond as Exclusive distributor of APEX DYNAMICS Taiwanese producer of planetary gearboxes is ready to give all related documents and help you to find suitable products for your use. For more information, please contact us.

What are the differences between these two?

- Internal operation:

Worm Gearbox: Composed of a conical screw (worm screw) along with a worm gear.

Planetary Gearbox: Composed of a series of gears and planets as the main elements.

- Application:

Worm Gearbox: Primarily use for increasing torque and reducing speed in industries requiring high torque and low speed, such as industrial machinery and heavy equipment.

Planetary Gearbox: Usable in various industries for more flexible motion transmission settings in terms of speed and torque, including automotive, aerospace, and energy industries.

- Speed and Torque:

Worm Gearbox: Tends to increase torque and decrease rotational speed.

Planetary Gearbox: Capable of providing various settings to maintain a balance between output torque and speed.

- Size and Weight:

Worm Gearbox: Typically, heavier in comparison to planetary gearboxes.

Planetary Gearbox: May have a smaller size and weight.

- Cost: Worm gearboxes usually incur higher costs.

The choice between a worm gearbox and a planetary gearbox depends on the specific

needs and conditions of each system. In general, worm gearboxes and planetary

gearboxes are two types of gear systems with different features and

applications. Our technician in Big Diamond is ready to help you to find your suitable

products based on your needs. For more information, please contacts us.