Sensors use in automation to track and measure a variety of physical factors, including temperature, pressure, flow rate, distance, and location. They are used to gather information about the environment or the automated process, which is then sent to a control system so that it may utilize it to decide what to do and how to do it.

Sensors frequently use in automation to check if a machine or system is functioning properly and within predetermined limits. For instance, sensors can be used in a manufacturing facility to determine if a machine is operating at the proper speed or whether a product is being produced within the necessary tolerances. The control system may respond appropriately, halting the machine or changing the process settings, if a sensor identifies a problem and sends a warning to it.

Some common types of sensors used in automation include temperature sensors, pressure sensors, proximity sensors, flow sensors, and position sensors. These sensors can use in a wide range of applications, from industrial automation to building automation to home automation, to improve efficiency, productivity, and safety.

what are the Criteria for selection?

Depending on the particular application and needs of the system being automated, different sensor selection criteria may apply. For choosing sensors, you should consider below points as well :

- Measurement range: The sensor should be able to measure the range of values required for the specific application.

- Accuracy: The sensor should have sufficient accuracy to ensure that the measurements are reliable and within the required tolerances.

- Resolution: The sensor should have a resolution that is appropriate for the specific application.

- Sensitivity: The sensor should be sensitive enough to detect the smallest changes in the measured parameter that are relevant to the application.

- Response time: The sensor should have a response time that is fast enough to detect and respond to changes in the measured parameter.

- Reliability: The sensor should be reliable and durable, with a long lifespan and minimal maintenance requirements.

- Environment: The sensor should be able to withstand the environmental conditions of the specific application, such as temperature, humidity, and vibration.

- Cost: The sensor should be cost-effective and provide good value for the required performance and reliability.

- Compatibility: The sensor should be compatible with the control system and other components of the automation system.

By considering these criteria when selecting sensors for automation, it is possible to choose the best sensor for the specific application and ensure optimal performance and reliability.

How to maintaining sensors in automation?

In order for sensors to continue to give precise and trustworthy measurements, you must maintain it. Below are a few general suggestions for maintaining sensors:

- Regular cleaning: Dust, dirt, and other contaminants can accumulate on the sensor and interfere with its measurements. Therefore, it is important to clean the sensor regularly with a soft, dry cloth or brush.

- Calibration: To guarantee accurate measurements, the sensor may need to be recalibrated if its precision drifts over time. The frequency of calibration depends on the specific application and the manufacturer’s recommendations.

- Inspection: Regular inspection of the sensor can help detect any signs of damage or wear and tear, such as cracks or corrosion. After inspection, if you find any damage, you have to replace or repair as necessary.

- Protection: Depending on the application, sensors may be exposed to harsh environments that can damage them. It is important to protect the sensor from exposure to excessive heat, moisture, or other harmful conditions that can affect its performance.

- Replacement: Sensors have a limited lifespan, and after a certain amount of use, you have to replace it. It is important to follow the manufacturer’s recommendations for replacement intervals to ensure continued accuracy and reliability.

Considering these maintenance tips, you can help ensure that your sensors in automation continue to perform optimally, providing accurate and reliable measurements for your automation system.

Example for Types of sensors in automation

Temperature sensors:

Temperature sensors are electronic devices for measuring temperature in various applications, from industrial to medical to scientific. They can detect the temperature of a wide range of materials and substances, including gases, liquids, and solids.

Automation use a variety of temperature sensors, including:

- Thermocouples: A thermocouple is made up of two different metal wires that are joined together at one end. When the joined end is exposed to a temperature difference, a voltage is produced that can be measured and used to calculate the temperature.

- RTD (Resistance Temperature Detector): An RTD is a type of temperature sensor that reacts to temperature changes by changing its resistance, which form of a metal wire or thin film. Temperature determine by measuring the resistance change and using that information.

- Thermistors: A thermistor is a kind of resistor that adapts to temperature changes by changing its resistance. Temperature determines by measuring the resistance change and using that information.

- Infrared sensors: Infrared sensors measure the temperature of a surface using infrared radiation. They often use in non-contact temperature measurement, such as when monitoring the machinery and equipment’s temperature.

Temperature sensors widely use in automation to monitor the temperature of industrial processes, such as in manufacturing, food processing, and energy production. They are also use in heating and cooling systems, medical devices, and many other applications where temperature monitoring is important for safety, efficiency, and accuracy.

pressure sensors

Electronic pressure sensors are used in automation to measure the pressure of gases and liquids in a variety of settings, including manufacturing processes, automotive systems, and medical equipment. They are used to track and monitor automated systems by detecting and measuring pressure changes and converting those changes into an electrical signal.

Various pressure sensor types are using in automation, including:

- Strain gauge pressure sensors: These sensors use a metal foil or wire that changes its electrical resistance in response to changes in pressure. The resistance change measure and use for calculating the pressure.

- Capacitive pressure sensors: Capacitive pressure sensors use a diaphragm or other flexible element that changes its capacitance in response to changes in pressure. The capacitance change measure and use to calculate the pressure.

- Piezoelectric pressure sensors: These sensors use a crystal that generates an electrical charge in response to changes in pressure. The electrical charge measure and use for calculating the pressure.

- Optical pressure sensors: These sensors use light to measure pressure. you can use these kinds of sensors in harsh or corrosive environments where other sensors may be damaged.

Automation uses pressure sensors for a variety of tasks, from monitoring fluid pressure in pipelines and tanks to managing gas pressure in industrial operations. Additionally, they use for automobile systems like tire pressure sensors and medical equipment like ventilators and blood pressure monitors. Many automated systems must be able to monitor pressure precisely and consistently in order to function effectively.

proximity sensors

These kinds of sensors use for tracing the presence or absence of objects without physical contact. They use a variety of technologies, including infrared, ultrasonic, magnetic, and capacitive, to find items that are within their detecting range.

In automation, proximity sensors come in a variety of forms, including:

- Inductive sensors: These sensors produce a magnetic field using a coil and a high-frequency oscillator. When an object enters the magnetic field, it induces eddy currents in the object, which detect by the sensor.

- Capacitive sensors: Capacitive sensors detect the presence of an item using an electric field. The capacitance of the sensor alters when an object enters the electric field, which recognize and utilize to establish the object’s existence or absence.

- Ultrasonic sensors: Sound waves use by ultrasonic sensors to identify objects. The distance to an item calculate by the time it takes for a high-frequency sound wave that the sensor releases to bounce off things within its sensing range to return to the sensor.

- Optical sensors: Optical sensors use light to identify objects in their environment. To find items that are within their detecting range, they can make use of a variety of technologies, including infrared, laser, and LED light.

Proximity sensors use in a broad variety of automation applications, including locating items on conveyor belts, determining if parts are present in machines, and locating parts on assembly lines. They also utilize in robotics, safety systems, and other fields were determining whether an object is there or not is crucial to the proper running of the system.

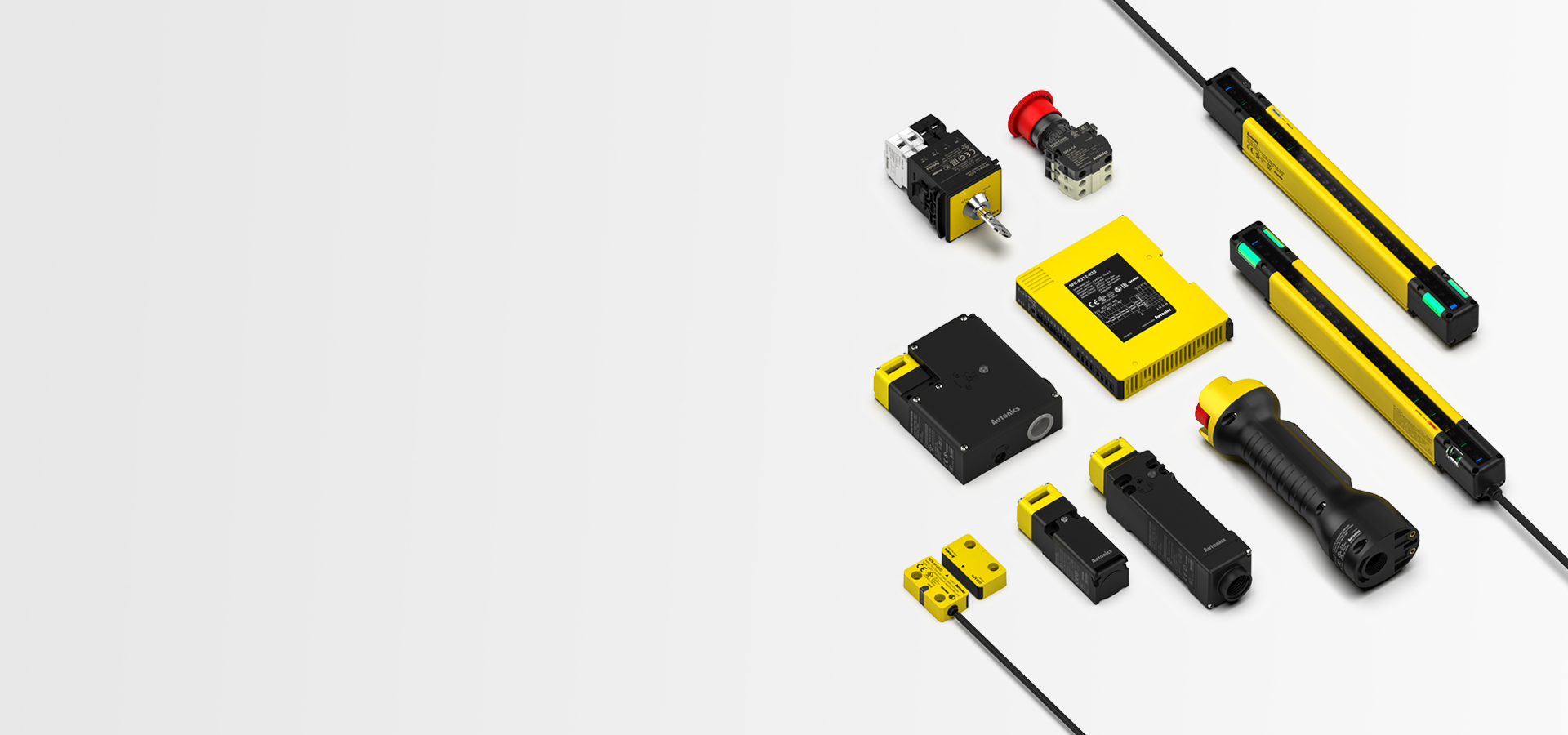

Big Diamond is working with well-known producers and Autnoics is one the best producer of sensors and controllers. We are distributor of Autonics products in Oman. We can help you to select suitable products for your automation system. If you have any question, please don’t hesitate to contact us.